Professional beekeeping in 2022+ will be efficient or will not be at all. Although at the beginning of this year many uncertainties weigh on many fields (editor note : this was written even before Russia invaded Ukrania), it is certain that we are engaged, willingly or not, in an energy and environmental transition. Commercial beekeeping will not escape this groundswell. Businesses have to evolve to more sustainable operations, it is a certainty. In this article, we will explore why and how transportation costs can be optimized..

The key levers

What are the levers that can be used to make this transition? What strategy should be implemented to ensure the farm sustainability?

And if we take our ambitions even further: Would it be possible to adopt a win-win strategy that would not only preserve, but even improve operational margins while being more environmentally friendly?

As for any strategy, the answer is not straightforward, nor the solution is deployed overnight. But there are some trends to explore. The sooner they are considered, the smoother the transition. Neglecting them is to postpone to tomorrow issues which in the long run can weigh heavily on the balance sheet of the operation and on the beekeeper's mood.

Clearly three major factors are affecting the economic trajectory of any operation:

- Optimize transportation

- Improve workforce management

- Improve adaptation to weather and climate

In other words, with the same beekeeping and commercial skills, the beekeeper who has made progress in these three areas will see a brighter future. For sure, acting on these three factors, it is to bring value and profitability to its exploitation.

In the next lines, we will focus on the first point: Optimize transportation.

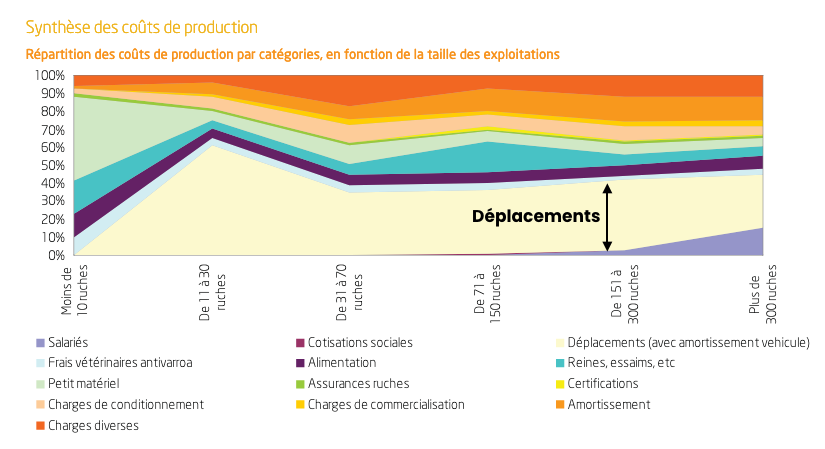

Transportation is THE major item in production costs

A beekeeper is a farmer with no land owned. As such, he has to move among his different locations. Whether they are sedentary or transhumant, these apiary yards are located between 20 and 200 km from the farm.

These trips are both a financial load for the company and the main source of carbon added to the product.

In its financial audit of the beekeeping business in 2012, FranceAgrimer (the french department of agriculture) was already pointing transportation as the most prominent cost item.

Ten years later, it is not too risky to think that this ranking remains relevant. Even more so at the beginning of this year, given the current spike in fuel prices (€1.70/l at the end of January). Thinking about optimizing transportation is tackling a real issue.

Properly evaluate transportation costs

For an apiary located at 60km from the farm, to which we would make 4 round trips on a nectar-flow, costs are computed as follows:

0,601 x 60km x2 A/R x 4 trip = 289€

(full transportation costs)

Coefficient 0,601 is obtained from tables of mileage allowance defined by the french government. This coefficient takes into account not only the fuel consumption, but all the costs associated with the ownership of the vehicle (maintenance, wear and tear, etc.). Clearly, it is 60 EUR cents per kilometer

A common mistake is to take only fuel costs into account:

1,65€/liter x 7liter/100 x 60km x 2 return trip x 4 trips = 56 € (no loading)

1,65€/liter x 15liter/100 x 60km x 2 round trip x 4 trips = 118 € (full load)

(fuel costs only)

Obviously, this is only 56/289 = 20% of the expenses. Don't be fooled, use the right formula!

The further away it is, the more expensive and the riskier.

The further away it is, the more expensive, and also the more risky. Making the way back with no harvest is equivalent to a net loss. And everyone knows that this possibility is to be taken seriously nowadays.

Do not load the product with CO2

Also has to be taken into account that transpot has a collateral effect: If we translate the transport costs into emissions, 116 kgCO2/mileage are emitted (still for an apiary at 60km)

In summary

Clearly any initiative reducing transportation will have a fourfold benefit:

- Reduce business expenses

- Reduce lost time on the road

- Reduce C02 emissions

- Improve quality offered to the customer with a product that is less CO2 loaded

What solutions to optimize transportation?

Having this background set, what are the options to consider? Here are some ideas:

Review your geographical operation footprint

First of all, it is certainly useful to review the current layout and identify if it is possible to tighten up the yards. This is a common sense action that becomes topical when diesel prices are high as they are now.

However, it is not always possible to bring the whole operation close to head quarters. In this case, it is necessary to consider an approach to optimize travel. Moving to the yard, yes, but not at any time or in any way.

Invest within a Decision Support Tool (DST)

A decision support tool can certainly help to increase efficiency. Here we are not only talking about hive monitoring with scales to identify the beginning of the nectar-flow, the subject is much broader and more methodical too:

First thing is being able to assess the potential of nectar-flows. If conditions are not suitable and distance to the yard important enough, what is the point in installing hive scales?. The most wise decision is not moving. This results in zero production, but also zero costs. Within MyBroodMinder the Nectar flow index helps assessing that risk.

If the decision to move is made, then the best hives should be loaded. Leave the average hives for later on. Here the brood index is the most useful tool for making this selection.

And once on site, you can remotely evaluate the progress of the operations with the help of several hive scales and brood probes. Although these measurements are extremely useful, they can only offer a view of the past, they are "rearview mirrors". At BroodMinder we like to look through the future, and since last year we have developed tools to make a 10 days forecast on the awaited evolution.

The beekeeper then makes a rational analysis at time t and projects it on a horizon of t+10 days. After running this exercise, the options become more explicit.

Should I go to inspect?

If yes, when?

With what kind of hardware : suppers or feeding?

Do I have time to act or this is urging?

This practice, which top beekeepers are increasingly adopting, is the winning approach to optimize transportation and in the end, achieving a profitable operation. And the good news is that these tools, whether hardware or software, are getting better every day to make it even easy in the future.

Summarizing, the return over investment of an apiary monitoring equipment is less than 12 month considering the savings (and the comfort) it allows. In this post we have talked about transportation, but there are other benefits that I will deal with in a future post...